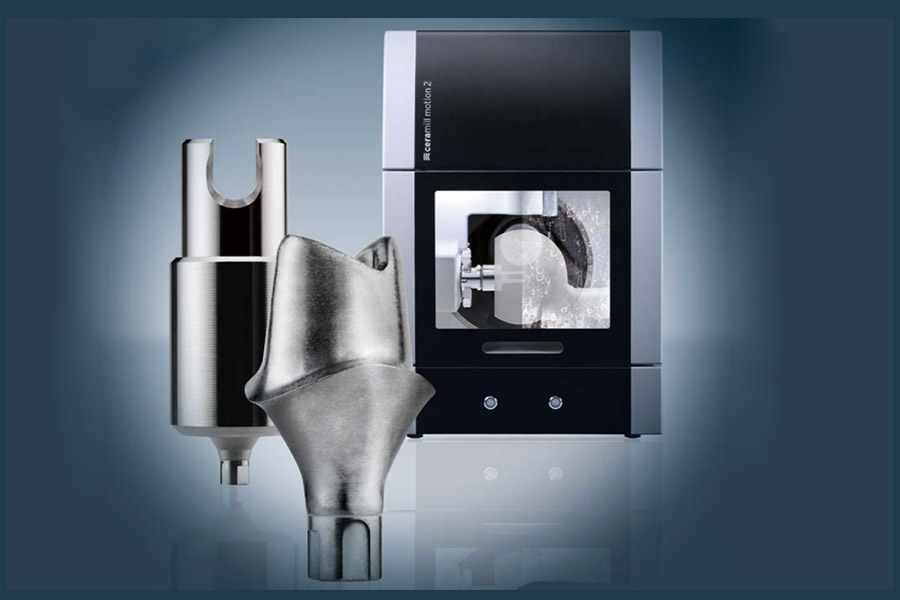

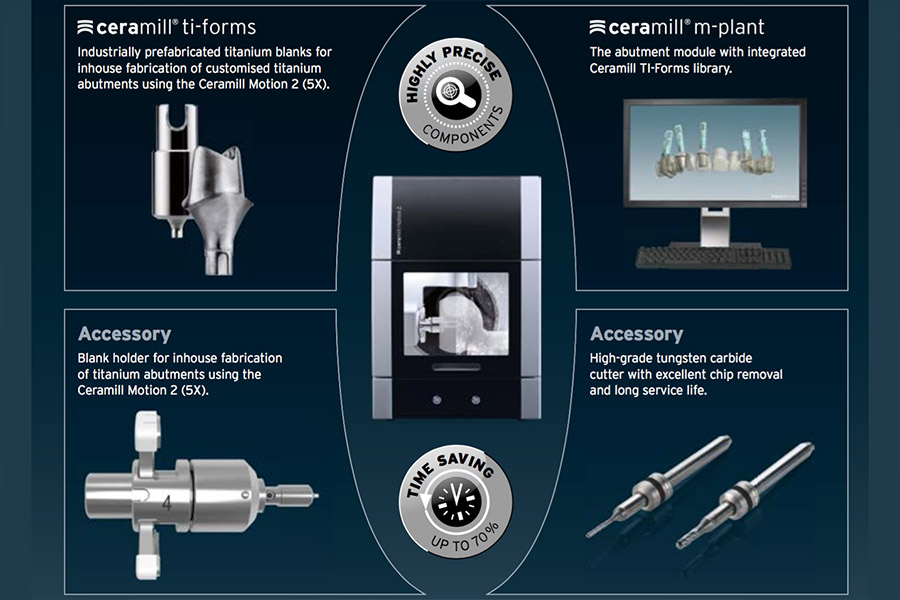

With the “Ceramill TI-Forms” Amann Girrbach presents titanium blanks with precisely prefabricated connection geometry suitable for a wide range of implant systems available for inhouse pro- cessing. What was previously only possible via industrial manufacturing centres and large milling systems, is now possible in the familiar high quality using the Ceramill Motion 2 (5X) and “rotational milling” technology in the wet milling mode.

In contrast to conventional milling in which the blank mainly remains in a static position, during so-called “rotational mill- ing”, in the wet mode the blank rotates continuously around its own axis. This not only saves the travel paths of the cutter but also ensures uniformly homogeneous material removal and surfaces with both a precise and smooth finish. With full value creation the user profits from savings in both time and precision. Only an adapter is required with which already installed Ceramill Motion 2 milling machines can be upgraded.